Aseptic Isolator

GloveFAST Aseptic

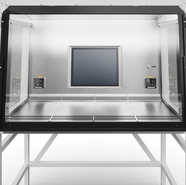

The GloveFAST Aseptic is a positive pressure isolator with vertical laminar air flow. A closed system ensures maximum personal and product protection. Thanks to numerous options, the isolator can be individually set up for any process.

Processing of:

- TPE / TPN compounding

- IV-solutions

- Eyedrops

- Stem cells

- CIV AS

- Sterility Test

The GloveFAST Aseptic positive pressure isolator is opionally available with an integrated FASTER NHP-system - find out more.

Features

- Air quality of cleanroom class A (Laminar Flow) as per EU-GMP Guide within the complete work zone and DIN EN ISO 14644-1 class 3

- Conform to EN ISO 14644-7, EN 61010 (electric installation), VDE / DIN 57789 (test), VDI 2083-1 and VDI 2083-3 (qualification)

- The outer and inner surface, the stainless steel work surface and the multi-functional control are easy to clean

- Safe and consequent separation of process and operator due to a closed system

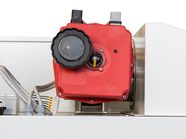

- Positive pressure operation (+75Pa) with laminar airflow and actively regulated blowers

- Aseptic system for changing gloves

- Display of internal pressure with delayed ambivalence time, automatic test and display of pressure decay (data are stored by the control)

- Easy surveillance, test and maintenance. In case of failure the remote control function enables our service to log in the unit via network (cost-savings in service).

- High operators’ comfort, easy operation and good visibility with ergonomically design

- Quick clean-up of contaminated air and rapid disposal of disinfection agents by high air-change rate within the work zone and the hatches

- Foot switches for hatch doors, as well as an interlock system

- Transfer tablets in hatches

- Multi-functional touch-display (size 7")

- Stand-by circuit and night-operation mode

- Documented and tested quality (IQ / OQ)

- Good price-performance ratio compared to custom-made Isolators

Aseptic Isolators of latest generation – High-Tech for your laboratory

Basically the Isolator consists of powder-coated sheet steel but can also be constructed entirely of stainless steel. The work chamber and the removable work surface is made of stainless steel.

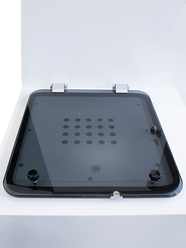

The front visor offers with a either 2 or 4 integrated glove ports (diameter of 300 mm) and allows comfortable working. For cleaning purposes it can be turned up and is helt in open position by gas pressure springs.

During operation the visor-gasket is pressed against the Isolator by three knurled screws. The Isolator is connected gas-tight to the hatches with a static gasket.

Transfer hatches:

The transfer hatches at both sides are fitted with a sliding transfer tray as well as inner and outer doors. For safety reasons the doors are electromagnetically interlocked (with a pre-settable delay program) so that only one of them can be opened. Each hatch is ventilated via a prefilter G4 and two HEPA filters H14. This ensures that no particles can enter the work zone or escape to the ambient.

Transfer hatch doors (hinged doors):

Outer and inner doors are of hinged type. The former open upwards but can optionally be opened from right to left or vice versa. The mechanism is operated by a key or a second key at the display. The inner hatch doors are operated by a foot switch or a second key at the display and open from front to back. Advice: You do not loose space in the work zone by the hinged doors, since the sliding transfer tray offers additional space.

Optional vertical hatch doors:

The inner vertical hatch doors are opened and closed by pressing a foot switch. The door slides vertically up and down. A pressure sensor grants security for the user, since the doors must no longer be opened manually, avoiding risk of injury. The complete workflow will be more economic and there is no cross contamination via the doors.

Air flow pattern:

The fresh air enters the work zone as laminar air flow and approximately 30% of the air is exhausted through the exhaust HEPA H14 hatch filters. The remaining 70% are guided through the circulation / downflow HEPA H14 filter.

Filter:

As per DIN EN 779 the prefilters are coarse dust filters of class G4 and are essential for longer lifetime of the H14 hatch filters. They can be taken out from the filter frame without tools and therefore be replaced without contamination. The other filters are HEPA filter (High Efficiency Particulate Air Filter) with nominal separating rate of 99,995%. They comply to DIN EN 1822 as filter class H14.

DEHS-filter-test:

Test ports allow to test the HEPA filters (main filter H14, circulation air filter H14, exhaust air filter H14 and hatch filter(s) H14) on separating rate and leakage. All ports are accessible from the front.

Air classifications within the work zone:

Air classifications are standardised:

- EU GMP, Grade A

- BS 5295 (1989) Class F

- ISO Class 3 as per DIN EN ISO 14644-1

Air pressure:

An optical and acoustic alarm is released when excessing the preset alarm values.

Air speed:

The vertical, unidirectional displacement flow (laminar flow) in the work zone is approx. 0,45 m/s. In case of unintended sleeve opening the airflow into the chamber is ≥0,7 m/s (Regulation of 0,7 m/s as per DIN EN 14644-7). The air speed inside the chamber is adjustable in certain limits with the vertical airflow blower.

Particle monitoring in the Isolator:

The particle counters PZG-series are user-friendly, versatile to be linked in terms of data, portable and with immense capacity. The The compact measuring instruments in elegant stainless steel housing have a color touch-screen display and are used by experts in filter tests, in semiconductor industry and pharmaceutical industry, in hospitals and pharmacies as well as in various other production processes. The PZG models measure particle sizes from 0,2 μm at a flow rate of 28,3 l/min and sizes from 0,3 μm at 100 l/min. They can display up to eight particle sizes simultaneously.

The particle counters can be used as independent measuring system or as component of entire particle monitoring.

The units are fitted with two interfaces (ETHERNET and USB). Data reports are generated as per all importants standards: DIN EN ISO 14644-1, DIN 1946-4, CFM, GMP at rest and GMP in operation.

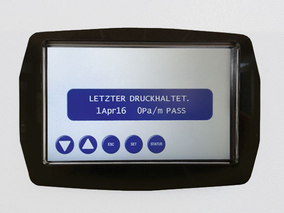

Regulation and Control with HMI Touch Panel

The isolator has a multi-function touch display with measured value display and scrolldown function. The Isolator does not indicate the differential pressure in an analog way. The control panel menu has the following functions:

- Counter for operation hours (hours, minutes)

- Date and time of the last service (password-protected)

- Date and time of the last pressure test plus information about passing or failing

- Measured values of pressure test (Value 1, Value 2, usw.)

- Remaining lifetime of the filter

- Capacity in percent of the exhaust air blower

- Capacity in percent of the circulating air blower

- Inner and outer temperature

Password protected control:

Alarm limits or hatch-lock times can only be changed after entering a password.

PLC-control alarms visible via display:

- Laminar Air Flow

- Work zone pressure

All alarms are free adjustable.

Automatic Pressure Decay Test:

To ensure that the isolator and hatches are completely tight, the isolator independently performs every minute a pressure test. Positive pressure (of approx. max. +200 Pa) is build-up, then holding time. When a pressure of +150 Pa is reached, measuring starts automatically. The values (3 measurings in total) are stored from the PLC and available via display.

Criteria: pressure decay of 25 Pa per minute.

In case of a higher decay the message „Pressure Test Fail“ appears on the display. For a pressure decay less than 25 Pa per minute it will show „Pressure Test Pass“.

Power breakdown:

In case of a power breakdown, an acoustic alarm powered by a separate battery is released. Optionally it is possible to work on up to 20 minutes with a uninterruptible Power Supply (UPS).

Support

- Metal support, fixed, 800 mm high

- Option: entirely of stainless steel 1.4301

Gloves and sleeves

The separately changeable glove and sleeve combination allows to change gloves without breaking the clean atmosphere inside the work chamber. Furthermore has the large opening the advantage of better mobility and persons of different body size can operate the unit without problems.

Double-glove system

The innovative Biogel Eclipse™ Indicator is the ultimative solution in protection and safety, since it consists of two gloves: one green inner glove and one straw-coloured outer glove. The gloves are thinner and smoother than other ones and with its special inner lining they are easy to put on. They convince with their excellent sense of touch and wearing comfort. Perforations are indicated with a green spot on the outer glove. The patented double-glove system detects 97% of the perforation.

Easy-Change Cuff Ring System (push / push)

With the easy to exchange ENVAIR Easy-Change cuff ring system of ENVAIR gloves can be changed aseptic without breaking the integrity of the surrounding area – operater an products are protected likewise.

Optional Isolator equipment

- Nitrogen, compressed air and vacuum connections

- Interface with RJ 45, RS 232, and USB

- Connection for air sampler

- Water-protected sockets IP 66

- H2O2-gassing, H2O2-hatch

- Adjustable support stand (electrically)

- Two Isolators (double version) with central 3-way-hatch

- 3-way-hatch with connected Microbiological Safety Workbench

- Isolator with one hatch

- Inner vertical hatch doors (electric)

- Display of hatch pressure

- Suspension rod in work zone

- Isokinetic probe for particle monitoring

- Active charcoal filter

- Camera for process documentation

- Glove-leak-test disc with manometer

- 19" touchscreen monitor (flush-mounted)

- Work zone with scales

- Monitoring of humidity and temperature

- Entirely made of stainless steel

- Optional free contacts for on-site exhaust system and alarms

- Further options upon request

| Model Type | GloveFAST Aseptic 1.2 m | GloveFAST Aseptic 1.5 m | GloveFAST Aseptic 1.8 m |

|---|---|---|---|

| Standards | EN 1822, EN12469, EN61010-1, ISO 14644.1 | EN 1822, EN12469, EN61010-1, ISO 14644.1 | EN 1822, EN12469, EN61010-1, ISO 14644.1 |

| Overall Dimensions (W×H×D, mm) | 2510 × 2450 × 868 | 2815 × 2450 × 868 | 3120 × 2450 × 868 |

| Useful Dimensions (W×H×D, mm) | 1192 × 740 × 580 | 1497 × 740 × 580 | 1802 × 740 × 580 |

| Air Flow (m/s) | 0.45 | 0.45 | 0.45 |

| Electrical Data | 230V, 50Hz, single phase ≤ 240 Watt | 230V, 50Hz, single phase ≤ 240 Watt | 230V, 50Hz, single phase ≤ 240 Watt |